Overview

We briefly present KG-CAIP (Knowledge Graph for Causal Analysis of Industrial Processes), a tool developed by SCCH within the Horizon Europe TRINEFLEX project (Grant No. 101058174). The tool automatically transforms raw industrial sensor data into interpretable knowledge graphs, making complex process interactions transparent and explainable.

Unlike traditional black-box analytics, KG-CAIP focuses on understanding cause–effect relationships over time. By combining data preprocessing, correlation analysis, and causal discovery, the tool enables engineers to visually explore how process parameters influence each other, supporting root-cause analysis, process optimization, and more informed decision-making. The approach was demonstrated using a real industrial scenario, underlining its direct applicability in practice.

This work reflects SCCH’s broader mission to bridge cutting-edge research and real-world industrial impact. We would like to sincerely thank Lolita Ammann, Michael Mayr, Jorge Martinez-Gil, and Georgios Chasparis for their major contributions to the development of the tool and its underlying methodology.

The scientific foundations of KG-CAIP are reported in the paper “Automated Knowledge Graph Learning in Industrial Processes”, recently published in Procedia Computer Science (Ref. [1]). The publication provides deeper insights into the methodological innovations behind the tool and its application to industrial sensor data.

Automated Knowledge Graph Learning in Industrial Processes

Industrial environments generate massive amounts of time-series sensor data, yet transforming this data into actionable and explainable knowledge remains a major challenge. The paper by Ammann et al. introduces a novel framework for automatically learning knowledge graphs (KGs) directly from industrial time-series data, with minimal manual intervention.

Core idea and approach

The proposed framework follows a structured pipeline consisting of:

- Data preprocessing and quality assurance, addressing missing values, categorical data, and stationarity issues common in industrial sensor streams.

- Correlation analysis, capturing instantaneous relationships between process parameters using multiple metrics (e.g., Pearson, Spearman).

- Causality analysis, based on a modified Granger causality approach with automated time-lag selection, allowing the detection of directional, time-delayed influences between variables.

- Knowledge graph generation, where correlations and causal relations are encoded as interpretable, queryable graph structures (e.g., RDF, SPARQL).

Key novelty

The novelty of the work lies in combining causal discovery and knowledge graph learning in an automated, end-to-end framework tailored to industrial processes:

- Instead of relying on black-box predictive models, the approach explicitly models causal dependencies over time, improving transparency and trust.

- The use of Granger causality with automated lag selection reduces the need for expert knowledge about process dynamics, which is often unavailable or incomplete in real industrial settings.

- The resulting knowledge graphs unify instantaneous correlations and lagged causal effects, offering a richer and more realistic representation of process behavior than static models alone.

Practical relevance

The framework is demonstrated on a real-world electrostatic particle transfer process, showing that the automatically generated knowledge graph aligns well with expert knowledge while also revealing non-obvious dependencies. This makes the approach particularly valuable for:

- Root-cause analysis

- Predictive maintenance

- Process optimization and control

- Explainable AI (XAI) in industrial environments

Overall, the paper positions automated KG learning as a key enabler for interpretable, data-driven industrial analytics, bridging the gap between raw sensor data and actionable process knowledge.

Use Case: Electrostatic Particle Transfer

To highlight the need for such a framework of automatically generating KGs that captures relationships between process parameters, the paper considers a real-world industrial use-case, commonly referred to as electrostatic particle transfer. It finds applications to different types of industries (e.g., dust removal, electrostatic dry powder coating in pharmaceutical industry, paper coatings, abrasive powders).

A typical setup of such a process is depicted in Figure 2 that describes the functionality of the electrostatic field in the case of the paper coating industry. In this case, the grains or powder is supplied to a conveyor belt through a funnel with an adjustable opening that regulates the flow of material. The conveyor belt moves the material through a static electric field formed by two parallel plates. The particles are first electrically charged (with the negative charge) and then attracted to the positively charged plate by electrical forces.

In the case of paper industry, the paper has already been coated with a special glue that helps the material to stick to the paper against the gravitational forces. The goal of the process is to create a desirable density of material (grains/powder) on the paper through the proper regulation of several configuration parameters, such as the flow of material, the current/voltage/frequency of the electric field, the distance of the plates at the beginning and at the end and the speed of the conveyor belt.

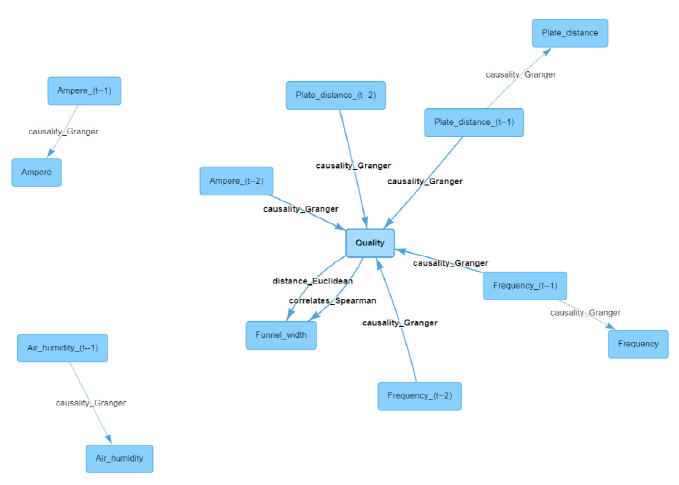

The following Figure 3 provides a glimpse of the types of networks generated by the KG-CAIP tool. It shows reasonable outcomes according to expert knowledge, since it indeed demonstrates the expected causal and correlation dependencies. For example, as expected, the plate distance, the frequency and strength of the electric field as well as the previous quality of specific time lags, causally influences the upcoming quality. Furthermore, the funnel width is instantaneously correlated with the quality (which is implied to be bidirectional). The graph also shows that there are no causal loops and no interactions between different parameter settings leading to hierarchical structures or process bottlenecks that lead to downstream restrictions.

Conclusions

The rationale behind converting time-series data generated through sensor measurements into knowledge graphs is to effectively address the challenges of extracting meaningful insights from large datasets. Moreover, applying Granger causality within this framework provides a method for uncovering causal relationships between sensor measurements. Despite Granger causality not representing causality in a rigorous sense it is helpful in time-series analysis as it identifies potential directed links, rather than mere similarity, between different sensor measurements over time. This capability is crucial for predictive maintenance, anomaly detection, and optimizing industrial processes, as it identifies root causes and predicts future events based on historical data. While the framework avoids the computational effort and loss of transparency typical for temporal knowledge graphs the KG still provides valuable insights into temporal relations. The framework captures instant relations as well as temporally shifted relations between parameters and allows investigation of temporal evolution in process structure by giving the user the possibility to apply the framework for specific time windows.

References

[1] Lolita Ammann, Jorge Martinez-Gil, Michael Mayr, Georgios C. Chasparis, “Automated Knowledge Graph Learning in Industrial Processes,” Procedia Computer Science, Volume 253, 2025, Pages 2428-2437,

ISSN 1877-0509, https://doi.org/10.1016/j.procs.2025.01.303.

Leave a comment