Motivation

Often in industrial processes, batches of material are processed sequentially and repeatedly through a deterministic sequence of process steps. Operators may have difficulties to properly follow and supervise them especially when there is a large number of relevant sensor measurements to be monitored. Furthermore, although the current operating conditions may be considered normal, there might be “hidden” indications of abnormalities in the time-series data (e.g., small trends) that may soon lead to undesirable behavior. Unfortunately, even experienced operators may lack the ability or the appropriate level of attention to detect such “hidden” indications soon enough. It is definitely in the benefit of the operators to be continuously assisted by supervising data processing techniques that can detect such abnormal operating conditions at early phases and provide suggestions to the operators regarding improved process configurations.

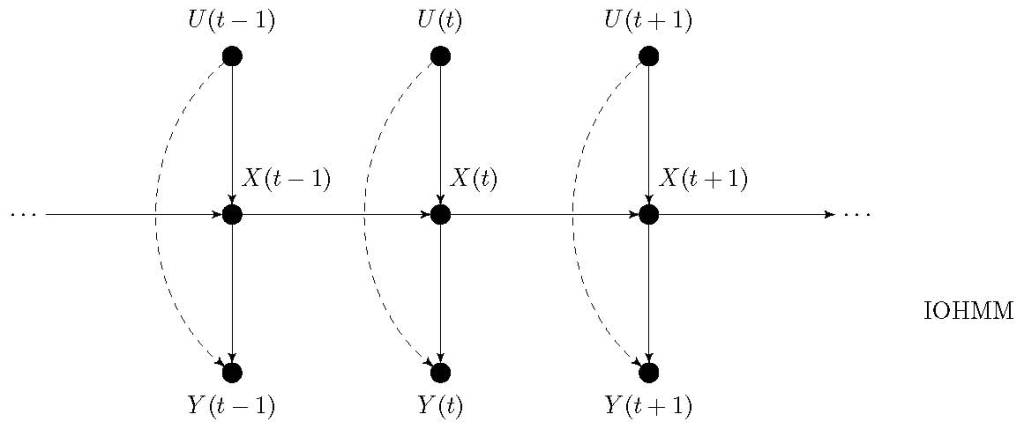

Traditionally, such inference problems in repeated processes can be handled in a rather straightforward manner via Input-Output Hidden Markov Models (IOHMM), introduced in [2], see e.g., Figure 1.

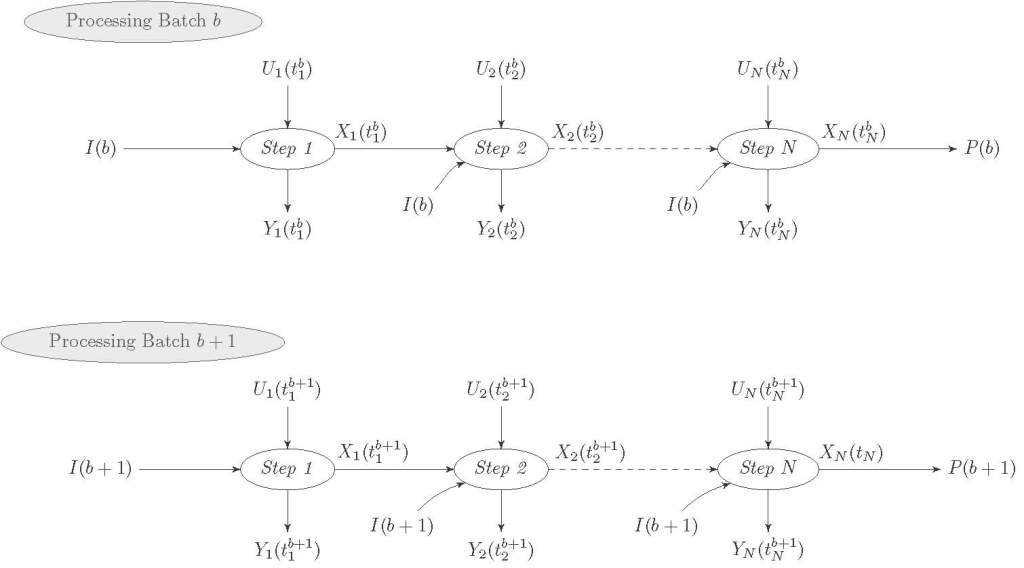

However, standard IOHMM are limited to repeated and identical processes, while industrial processes may comprise multiple non-identical process steps and possibly with non-standard contingencies between process steps. The following Figure 2 depicts a more general structure that better captures process lines and two different types of dependencies, namely a) temporal dependencies within the same process step (i.e., the operating condition of a process step may influence the operating condition of the same process step when the next batch is processed), and b) dependencies between adjacent process steps (i.e., the operating condition of the current process step may influence the next one). These two types of dependencies essentially exploit the Markov property governing most industrial processes, in the sense that in most cases it is the operating condition of the previous process step that most likely influences significantly the next process step, or it is the operating condition of the previous processed batch will most likely influence the next processed batch. However, in principle higher order dependencies could also be addressed through a similar structure. The scientific paper [1] that is presented in this post is only addressing one-step dependencies, the general architecture of which is depicted in the following figure.

To this end, in the research paper [1], we propose a generalization of standard IOHMM that it is more appropriate for modeling industrial process lines. Furthermore, we derive the update recursions for training such models and we show analytically that such update recursions guarantee an increase in the likelihood of the observation sequences, meaning that the trained parameters can better capture the observed data as the number of update iterations increase.

Sources

This short discussion has been based on the scientific publication [1]. The following references have also been used in the above discussion.

[1] Chasparis, Georgios C., Sabrina Luftensteiner, and Michael Mayr. “Generalized Input-Output Hidden-Markov-Models for Supervising Industrial Processes.” Procedia Computer Science, 3rd International Conference on Industry 4.0 and Smart Manufacturing, 200 (January 1, 2022): 1402–11. https://doi.org/10.1016/j.procs.2022.01.341.

[2] Bengio, Y., and P. Frasconi. “Input-Output HMMs for Sequence Processing.” IEEE Transactions on Neural Networks 7, no. 5 (September 1996): 1231–49. https://doi.org/10.1109/72.536317.

Subscribe to get access

Read more of this content and access the video presentation when you subscribe today.

Leave a comment