This short article/presentation was presented as part of the Digital Twin Best Practice Workshop organized by the Swiss Smart Factory and the Horizon Europe project Twin4Twin. In this presentation, I provided an overview of three main challenges in the integration of Data-based Digital Twins in Process Industry motivated by a series of recent projects of Software Competence Center Hagenberg GmbH and the SUSTAIN Research Focus (Scalable Sustainability Aware Optimization & Control) which I have the chance to lead together with my colleague M. Zwick. The article has also been published at Twin4Twin Atlas.

Abstract

Recent advances in sensor and edge data processing systems have created new opportunities for the creation of accurate digital representations (or digital twins) of physical processes (e.g., manufacturing processes). At the same time, the induced modeling tasks have grown in scale and computational needs, e.g., going from small scale control system technologies applied on a single machine or a single process step to modeling and supervising complete industrial process lines. Naturally, and due to the recent successes of deep-learning and neural networks, data-based modeling techniques and predictive data analytics have drawn significant attention as an alternative to physics-based modeling techniques. However, the implementation, integration and acceptance of data-based methods brings up several new challenges, namely a) integrating systems of different nature and modeling granularity, b) integrating expert/domain knowledge, c) handling unforeseen or new scenarios and operating conditions and d) the need for human-machine interaction. In this presentation, we will review some of the most prominent challenges in the implementation of data-based modeling techniques for predictive data analytics and optimization in process industry and discuss current practices for tackling them. The presentation of these challenges will be organized in three thematic areas, namely a) virtual sensors, b) industrial reactive optimization, and c) hierarchical predictive modeling and optimization.

Introduction

The implementation of data-based predictive analytics and digital twins faces challenges with respect to a) domain generalization (i.e., the ability of the model to perform equally well in different scenarios and operating conditions), b) complexity in decision support and reaction speed, c) human-machine interaction and explainability. In this presentation, we will discuss these challenges in the context of real-world industrial use-cases and discuss some of the current practices for tackling them. The presentation of these challenges will be organized in three thematic areas, namely a) virtual sensors, b) industrial reactive optimization, and c) hierarchical predictive modeling and optimization.

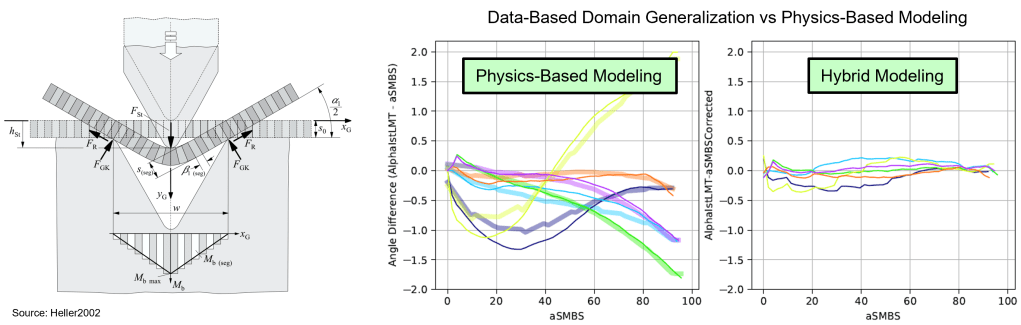

Virtual Sensors

In recent years, sensor and edge processing technologies allow for almost real-time monitoring of complex industrial processes. However, there might still be phenomena and process details that cannot accurately be monitored and regulated without including a form of prediction or simulation of the process evolution. An example is demonstrated in Figure 1 of the metal bending process. A set of sensors can monitor the process, however the operator requires a simulation of the upcoming evolution of the process in order to proactively regulate the applied force and achieve the desired final angle. The problem becomes even more challenging when we consider the case of different types of material and different scenarios (e.g., machine tools and configurations). We will present a framework for combining physical-based modeling techniques with machine-learning techniques in order to improve the prediction accuracy of the process evolution. Furthermore, we will present a methodology for domain generalization into multiple scenarios.

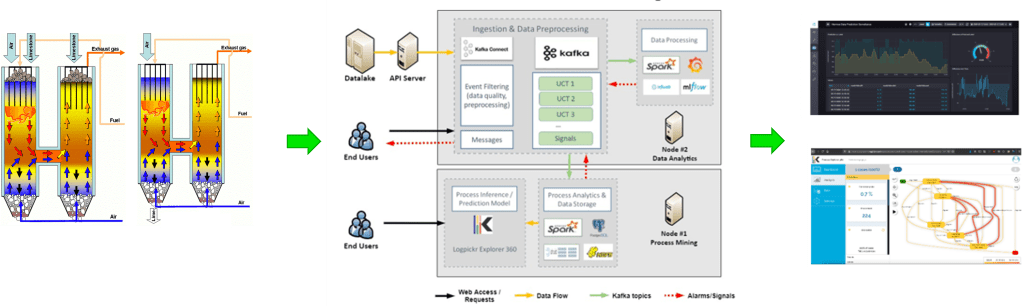

Industrial Reactive Optimization

Industrial processes could be highly complex due to the increased variability in the input and configuration parameters as well as the influence of unpredictable exogenous factors. In certain cases operators need to continuously monitor the sensor data and react within a few secondsby re-configuring the process parameters. Although operators might be quite experienced in regulating the process, often support is required from sensors, predictive modelsand digitaltwins to allow for more informative and quick decisions. In this part of the presentation, we discuss challenges and best practices in establishing a data processing pipeline for providing near real-time suggestionsto the operator.

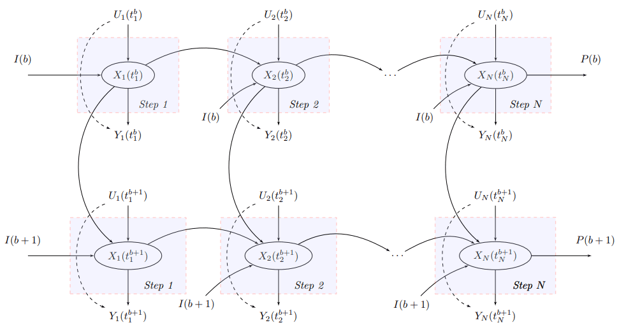

Hierarchical Predictive Modeling and Optimization

The traditional paradigm of a digital twin usually considers specific parts of the process or process steps. When there is a need for simulating, monitoring or predicting complex processes of possibly heterogeneous systems or multiple process steps, several new challenges emerge. Specifically, monitoring of the overall process by the operators becomes a great challenge given the potentially large amount of sensor data from different parts of the process, and the lack of better and more human-readable interpretation of the process operating conditions. In this part of the presentation, we present some techniques for providing a more human interpretable and understandable monitoring of the process through causal inference modeling techniques. Further information can be found at reference [Chasparis et al. 2022].

References

[Grubinger et al., 2017] T. Grubinger, G. Chasparis, and T. Natschläger, “Generalized online transfer learning for climate control in residential buildings,” Energy and Buildings, vol. 139, pp. 63–71, Mar. 2017.

[Zellinger et al., 2020] W. Zellinger, T. Grubinger, M. Zwick, “Multi-source transfer learning of time series in cyclical manufacturing,” J Intell Manuf 31, pp. 777-787, 2020.

[Luftensteiner and Zwick, 2021] S. Luftensteiner and M. Zwick, “A Framework for Improving Offline Learning Models with Online Data,” presented at the DBKDA 2021, The Thirteenth International Conference on Advances in Databases, Knowledge, and Data Applications, May 2021, pp. 32–37.

[Luftensteiner et al., 2021] S. Luftensteiner, M. Mayr, G. Chasparis, M. Pichler, “A Versatile Usable Big Data Infrastructure for Process Industry and Its Monitoring Applications,” Frontiers of Chemical Engineering: Computational Methods for Chemical Engineering, vol. 3, 2021.

[Kychkin and Chasparis, 2023] A. Kychkin and G. Chasparis, “Automated Cross Channel Temperature Predictions for the PFR Lime Kiln Operating Support,” 31st Mediterranean Conference on Control and Automation, 2023.

[Mayr et al. 2022] M. Mayr, S. Luftensteiner, and G. Chasparis, “Abstracting Process Mining Event Logs from Process-State Data to Monitor Control-Flow of Industrial Processes,” Procedia Computer Science, vol 200, 2022, pp. 1442-1450.

[Chasparis et al. 2022] G. Chasparis, S. Luftensteiner, and M. Mayr, “Generalized Input-Output Hidden-Markov-Models for Supervising Industrial Processes,” Procedia Computer Science, vol 200, 2022, pp. 1402-1411.

[Abbas et al., 2022] A. Abbas, G. Chasparis, J. Kelleher, “Interpretable Input-Output Hidden Markov Model-Based Deep Reinforcement Learning for the Predictive Maintenance of Turbofan Engines,” Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics), 2022, 13428 LNCS, pp. 133–148.

[Abbas et al., 2024] A. Abbas, G. Chasparis, J. Kelleher, “Hierarchical framework for interpretable and specialized deep reinforcement learning-based predictive maintenance,” Data & Knowledge Engineering, vol 149, 2024.

Leave a comment